The loads and stresses acting on steel structures out at sea (the origin of the word "offshore") are significantly greater than occur on land (onshore), as a result of environmental conditions such as wave motion and very low temperatures. The accessibility of exposed components is also in itself more difficult than onshore. This, of course, is why an even higher immunity to failure is demanded. This then necessitates not only very careful construction, but also the use of structural materials that are, on the one hand, easy to work and, on the other hand, possess excellent mechanical and technological properties.

To provide support to the client for his own extensive qualification provisions under the working conditions of the fabrication shop and of the project itself, not only the standard tests on samples of the plate material are performed in the case of offshore material, but also preliminary qualification tests on the material at the material producer’s works.

In order to preliminary qualify a specific grade of steel up to a certain thickness, the heavy plate producer must perform various tests both on the parent material and on welds made on the parent material. To compile a complete assessment of weldability - known as the "Welding Report (WR)" - a number of specimens are produced at various weld energy levels and, if necessary, in a number of different heat-treatment states. This procedure requires an enormous amount of work, especially in the case of thick plates. A key reason for this is the fact that, for a plate of a thickness of 208 mm, for example, up to 425 weld beads must be deposited. Dillinger then records the results in the WR, thus providing support for the customer when preparing welding and welding-related work.

The following parent material and weld properties are tested and recorded:

- Hardness, tensile strength and Charpy V‑notch toughness

- Fracture-mechanics crack tip opening displacement (CTOD) test for assessment of immunity to failure

- Documentation of welding parameters

- The Welding Report must be verified by competent independent third parties

The WR qualifies shipments of plates which have been produced using a comparable production route and have achieved analyses similar to those achieved by the material sampled and tested for the WR.

The regulatory basis of such preliminary qualification is provided either by the European Offshore Standards (EN 10225-1 / Norsok‑Standard M‑120) or by the American Offshore Standards (API 2W / 2Y).

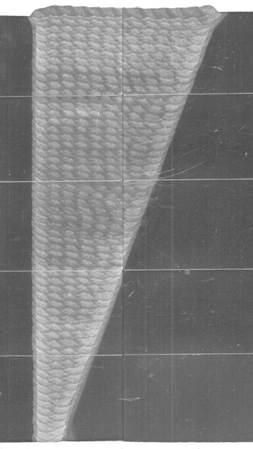

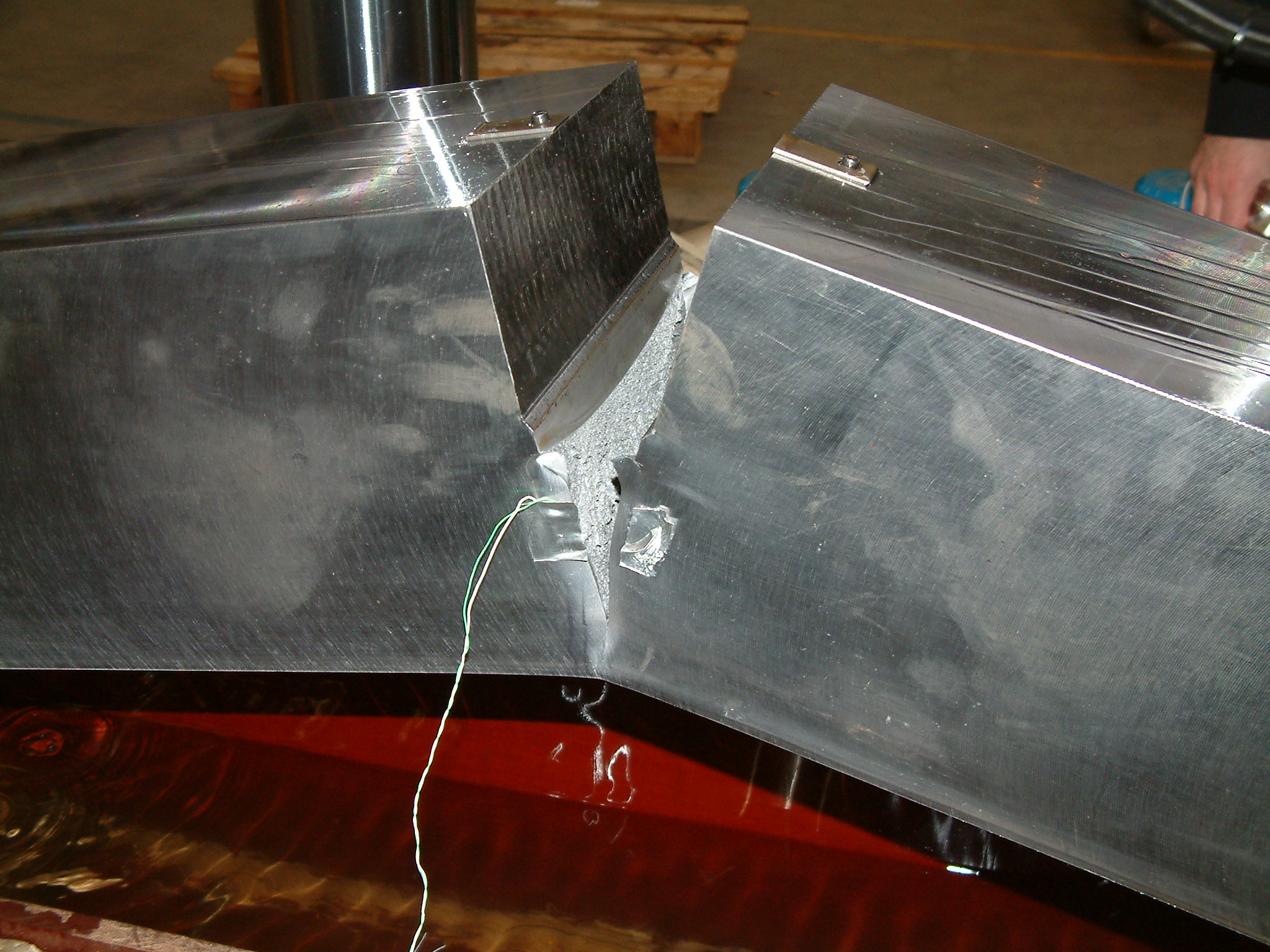

© Dillinger – CTOD specimen at the end of testing: the notch applied (top) and the steady-state fatigue crack connecting to it below can be seen. Strain gauges, which measure the opening of the crack in the bending-test machine until the crack begins to propagate, have been installed at the tip of the crack. The crack tip opening is measured, on the one hand, while the "nature" of the crack, whether ductile or brittle, among other things, is determined and recorded, on the other hand.

Aktien-Gesellschaft der Dillinger Hüttenwerke, Werkstraße 1, 66763 Dillingen/Saar, Telefon: +49 6831 47 0, Telefax: +49 6831 47 2212, Sitz: Dillingen/Saar, Registergericht: Amtsgericht Saarbrücken HRB 23001, Vorsitzender des Aufsichtsrats: Reinhard Störmer, Vorstand: Stefan Rauber (Vors.), Joerg Disteldorf, Daniël Nicolaas van der Hout, Dr. Peter Maagh, Markus Lauer, Jonathan Weber

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.