Where and when do we speak about PWHT?

The expression "post weld heat treatment", or "PWHT", is the international term for "stress-relieving annealing" and features very frequently in the most widely used codes and standards for structural steel and pressure equipment engineering. The relevant product standards, such as EN 10028, Part 3, for example, also include ordering notes relating to required time temperature parameter P, in the form of the Pcrit value.

When is stress-relieving annealing needed?

Many production processes specify PWHT after completion of welding. This post welding operation is applied with the aim of reducing the residual stresses caused by the heat input to the component during welding. There is, in addition, the possibility of adjusting the mechanical properties of the welded joint (consisting of the heat affected zone, or "HAZ", and the weld itself). In most cases, treatment of the weld takes place by means of a thermal operation. For this reason, insiders also speak of post weld treatment or stress-relieving annealing. Heat input and temperature control in this process is generally similar to that of tempering.

Two basic processes

In these thermal post welding treatment operations, the parent material is treated either partially or completely together with the weld: either only the weld is heat treated using locally applied "heating mats" or the whole welded component is placed in a heat treatment furnace. This depends, among other things, on whether the component is still undergoing the production process or is, instead, already installed and in operation. In the case of repairs on equipment already installed, such treatment is usually conducted locally, because removal from the equipment’s location would be too expensive and time consuming - or simply impossible!

Experienced steel makers like Dillinger will help you!

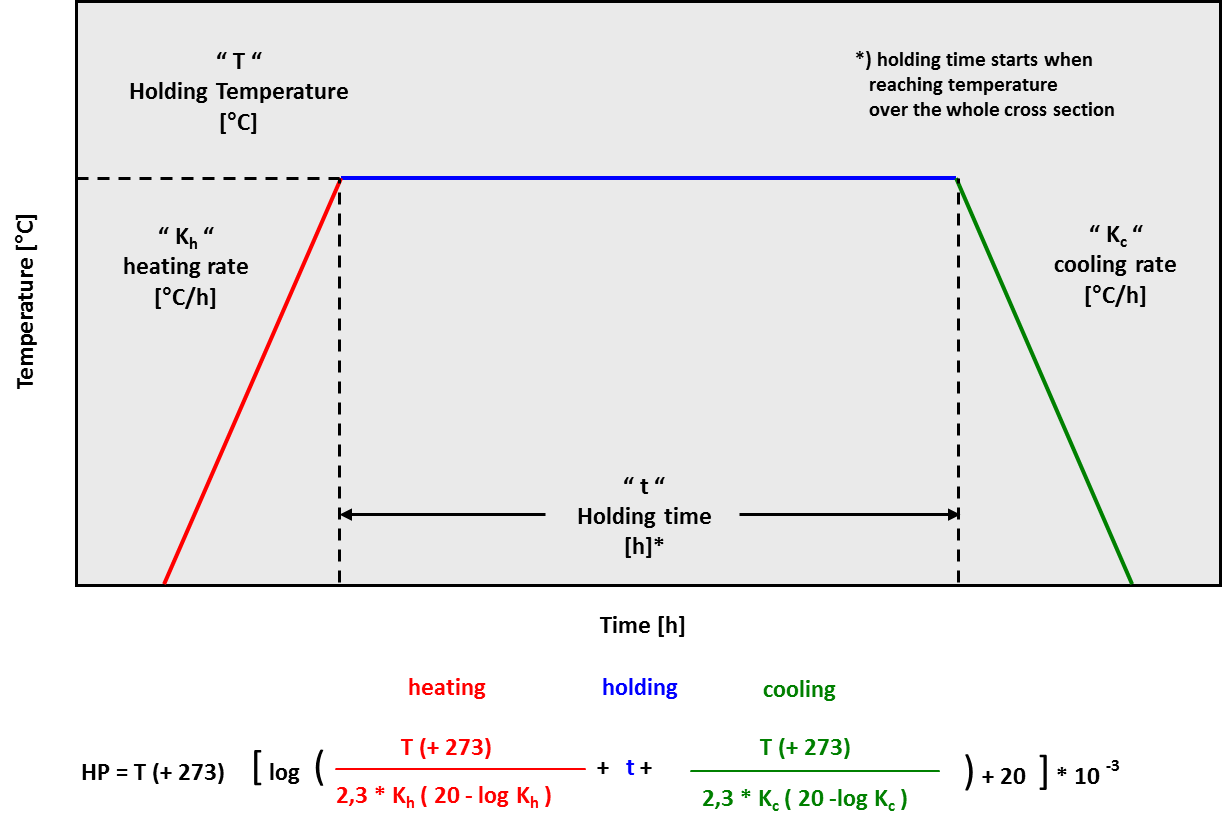

It’s always important to note when performing a PWHT process that the type of heat treatment applied to a steel is capable of altering its microstructure and thus also its mechanical and technological properties; this is a function both of the heating-up and cooling rates and, in particular, of the holding temperature and holding time. As a steel producer, we translate these parameters using appropriate equations into the so-called Larson Miller or Hollomon parameter. When an order for steel is placed, the experienced steelmaker will evaluate producibility in detail and apply concepts specially developed for this purpose. In this way, every steel customer can be sure of being "on the safe side" in his fabrication processes when using Dillinger heavy plate.

Digital help around the clock

Here, it’s a good idea to take a look at Dillinger’s E-Service area. The steel user will find here all the important digital welding aids and tools, including the Hollomon parameter mentioned above.

Hollomon parameter © Dillinger

Aktien-Gesellschaft der Dillinger Hüttenwerke, Werkstraße 1, 66763 Dillingen/Saar, Telefon: +49 6831 47 0, Telefax: +49 6831 47 2212, Sitz: Dillingen/Saar, Registergericht: Amtsgericht Saarbrücken HRB 23001, Vorsitzender des Aufsichtsrats: Reinhard Störmer, Vorstand: Stefan Rauber (Vors.), Joerg Disteldorf, Daniël Nicolaas van der Hout, Dr. Peter Maagh, Markus Lauer, Jonathan Weber

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.