Morocco is actively pursuing plans for the use of renewable energy sources, and hydropower will play a crucial role, in addition to the expansion of wind-power and solar energy. The Abdelmoumen pumped-storage plant, located in the south-west of the country, around 70 km from Agadir, is to commence its significant contribution to a sustainable energy future from 2022 onward. Abdelmoumen will cover not only Morocco's peak-load needs, but also simultaneously supply quickly available standby capacity for grid stabilisation.

© ANDRITZ Hydro

Special challenges demand special solutions

The special feature of this project, in addition to its two reversible 175 MW pump turbines, is its technically demanding headrace, with a length totalling 3 km. The water held in the upper reservoir is routed via a pressure line (the "penstock") with an extremely high net "head" (height difference) of 554 m into a lower reservoir. The steel-lined headrace consists of a – in some cases exposed – 2 km long penstock, more than 700 m of tunnel and three shafts with depths of more than 60 m. A hydroelectric plant with a capacity of 350 MW is located between the two reservoirs. The pump turbines are designed for twenty high-speed mode reversals per day to achieve rapid reaction and grid regulation.

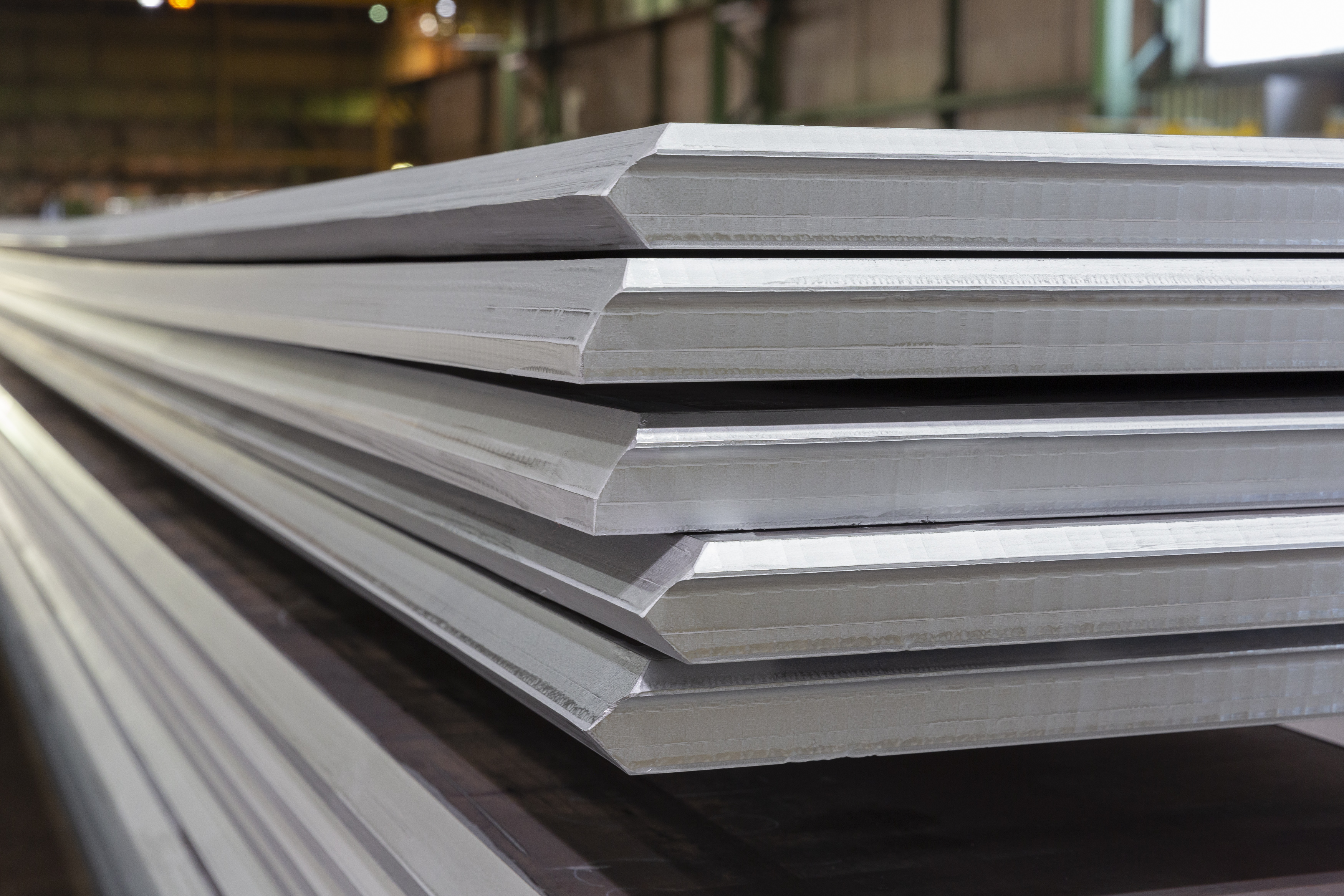

In view of the plate dimensions needed for the exposed sections of the penstock, the feasible maximum item weights were of special importance on this project: plate length in every case varies according to diameter. The larger item weights that Dillinger is able to supply signify, particularly in the case of thick plates, less limitation on length, and this enabled our customer to use only one longitudinal weld even with the large diameters necessary here.

Thermomechanically rolled plates of grade DI-MC 690 of up to 40 mm in thickness were used for the penstock. Plates of 60 mm thickness of grade S690 QL were used for the bifurcation, while a thickness of a whole 100 mm was used for the internal sickle plate in this bifurcation.

A special feature of this project, and therefore a challenge for the plant engineer during installation, was the exposed penstock of a diameter of up to 5 m combined with the climate prevailing at the site, since it was necessary during installation to take account of and compensate for the effects of the sun and of solar radiation.

© Dillinger

Dillinger's contribution

Dillinger supplied not only all the steel needed on this project for the new penstock (a total of 9,600 t of heavy plate), but also the preparation of the necessary welding work and on-site installation, by machining a milled edge on the plate material; in addition, Dillinger also delivered flame-cut components for production of shaped elements.

Around 5,000 t of high-strength thermomechanically rolled DI-MC 690 steel, a grade specially developed for use in hydropower engineering, were used for construction of this duct.

The penstock – facts and figures

Length: 3 km

Diameter: 3.6 to 5.0 m

Steel requirements: 9.6 kilotonnes

Special features: High materials requirements, milled welding edges, flame-cut components, just-in-time delivery to the site

Aktien-Gesellschaft der Dillinger Hüttenwerke, Werkstraße 1, 66763 Dillingen/Saar, Telefon: +49 6831 47 0, Telefax: +49 6831 47 2212, Sitz: Dillingen/Saar, Registergericht: Amtsgericht Saarbrücken HRB 23001, Vorsitzender des Aufsichtsrats: Reinhard Störmer, Vorstand: Stefan Rauber (Vors.), Joerg Disteldorf, Daniël Nicolaas van der Hout, Dr. Peter Maagh, Markus Lauer, Jonathan Weber

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.