So what is sour gas?

Sour gas is natural gas that is recovered containing hydrogen sulphide (H2S) as a gaseous impurity. Deposits of this "sour" natural gas can be found, for example, in the Middle East, in Kazakhstan and in the Far East.

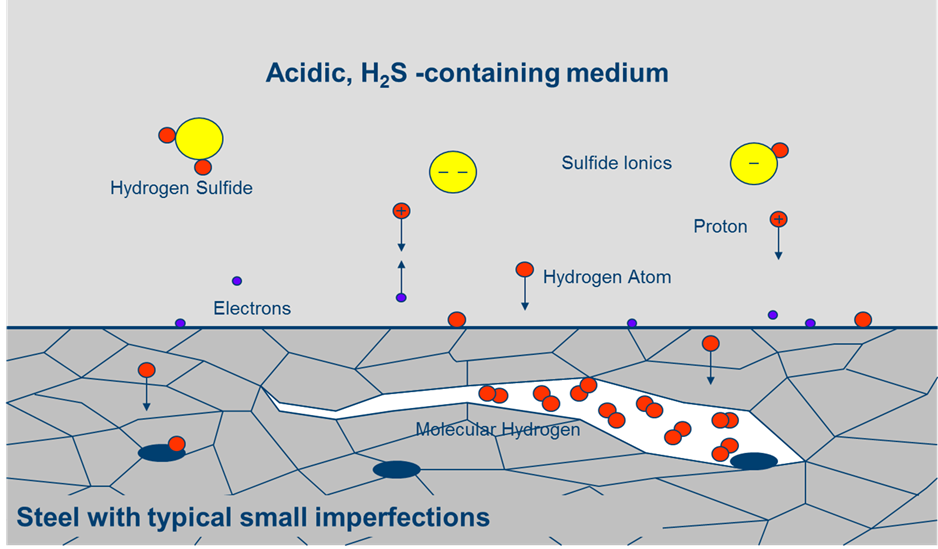

If sour gas is conveyed or processed in pressure vessels without drying, the condensation of water on the material's surface can result in a corrosion reaction.

In this reaction, H2S acts as a promoter, with the result that free disassociated hydrogen H+ accumulates in the steel as atomic hydrogen via adsorption and absorption processes. This atomic hydrogen can recombine to molecular hydrogen (H2) in the lattice of the metal at lattice defects, non-metallic inclusions, points of segregation and micropores and then cause cracking in the material, a phenomenon known as hydrogen-induced cracking (HIC).

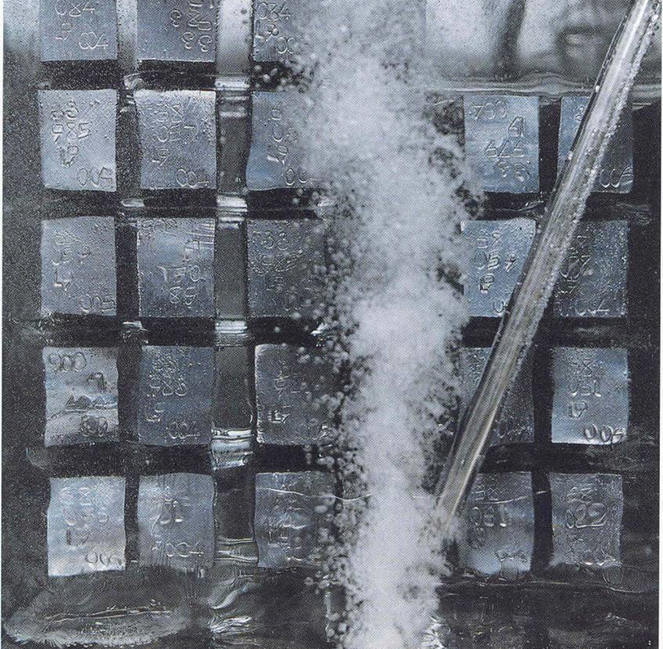

© Dillinger

In addition, cracking phenomena on specimens exposed to stress are also known and are likewise attributable to the absorption of hydrogen. These are referred to collectively as "sulphide stress cracking" (SSC).

Similar conditions with regard to the corrosion reaction with the corresponding damage mechanisms are also present in liquid media such as petroleum.

In order to prevent this damage to the greatest extent possible, steels which prevent the recombination of hydrogen, in particular, must be selected for use when the fluids mentioned are present.

Dillinger's reliable answer

At Dillinger, sour-gas resistant steels with a high "cleanness" (only few, homogeneously distributed, inclusions) are produced under the strict application of a far-reaching quality-assurance system during all stages of production. These steels, thanks to their cleanness and their homogenous, fine-grained microstructure, provide hydrogen with fewer opportunities for recombination and thus fewer opportunities for the occurrence of problematical cracking. Whether for sour-gas resistant plates for the linepipe sector or our proprietary steels DICREST, DIROS and DI-TANK for pressure vessel fabrication – Dillinger's product portfolio assures exactly the right solution for a whole range of applications. Visit our website to find more information and the person to contact at Dillinger for these steels.

Test receptacles for the HIC test (© Dillinger)

Aktien-Gesellschaft der Dillinger Hüttenwerke, Werkstraße 1, 66763 Dillingen/Saar, Telefon: +49 6831 47 0, Telefax: +49 6831 47 2212, Sitz: Dillingen/Saar, Registergericht: Amtsgericht Saarbrücken HRB 23001, Vorsitzender des Aufsichtsrats: Reinhard Störmer, Vorstand: Stefan Rauber (Vors.), Joerg Disteldorf, Daniël Nicolaas van der Hout, Dr. Peter Maagh, Markus Lauer, Jonathan Weber

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.