Borssele is an offshore wind farm located in the Dutch exclusive economic zone (EEZ) of the North Sea and consisting of four lots (I, II, III and IV) generating some 350 MW each and a fifth, smaller lot (20 MW) for the installation of innovative demonstration equipment. The wind farm as a whole is designed for generation of 1,500 MW.

Borssele I and II – Dillinger steel supports the energy turnaround

With a total generating capacity of 752 MW each, the Borssele I and II sectors will supply around a million Dutch households with clean electricity. In addition, they will also contribute to the decarbonisation of coastal industries: a new electrolysis system delivering the hydrogen for carbon-neutral fertiliser production will also be powered using renewable electricity.

The Borssele I and II sectors were, upon their commissioning in November 2020, the largest wind farm in the Netherlands and the second largest operational offshore wind farm in the world. Occupying an area of some 128 km², the wind farm consists of 94 Type SG 8.0-167 DD wind turbines and an offshore transformer substation. The 8 MW Siemens Gamesa offshore wind turbines have been installed here for the first ever time in a commercial project. Their dimensions are extremely impressive, with a total height of 200 m and a rotor diameter of 167 m.

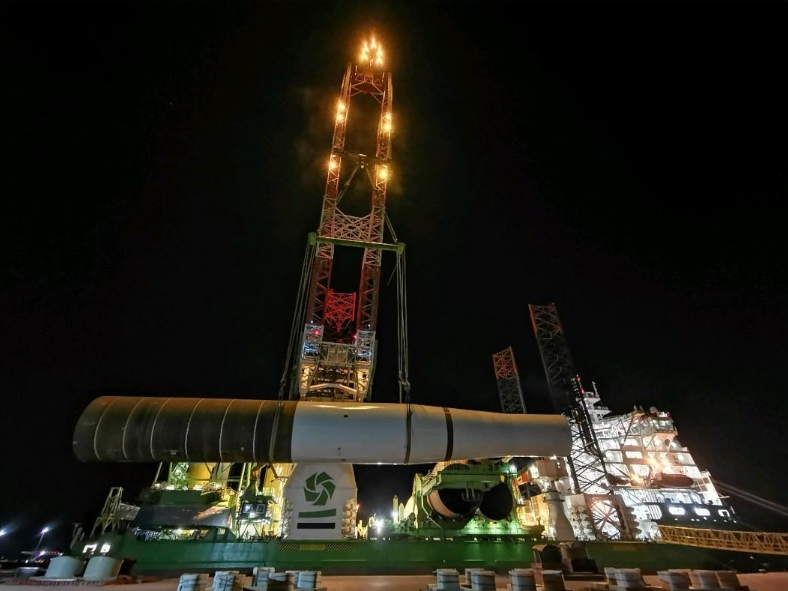

They are located in water of depths varying from 14 to 38 m and are mounted on monopile foundations with diameters of up to 8.3 m, lengths of up to 76 m and weights of up to 1,188 t. Dillinger supplied around 105,000 t of heavy plate in thicknesses ranging from 30 to 108 mm for these monopile structures. A further approx. 3,700 t of Dillinger steel can also be found in the transformer substation situated at this wind farm (Borssele Alpha).

Borssele III and IV – Dillinger's potentially record-breaking TM plates

The 77 wind-energy generators with which the two lots III and IV are equipped are capable of supplying around 825,000 Dutch households annually with environmentally safe electricity, saving more than one million tonnes CO2. The 77 MHI Vestas V164 9.5 MW machines are also carried on monopiles. A large number of thermomechanically rolled plates with item weights of a potentially record-breaking > 40 t were used for the monopile foundations, permitting optimised welding and handling. Each monopile is 85 m long and weighs 1,280 t. Dillinger supplied around 70,000 t of heavy plate for these monopile structures.

Borssele V – Dillinger steel helps innovation

The Borssele V offshore wind energy lot is designated a demonstration site at which technical innovations are to be installed and tested. This special wind farm is to start generating during 2021 and will provide clean energy for 25,000 households.

The topic of "size" again plays a special role here, since the trend toward higher-output turbines also means that all the other components need to developed from new – providing ample opportunities for innovation and for Dillinger's heaviest-ever thermomechanically rolled plates. At Borssele V, for example, two MHI Vestas 9.5 MW turbines are used; they are mounted on monopile foundations. The heaviest thermomechanically rolled plates ever produced at Dillinger, each weighing in at individual item weights of around 42.7 t, were used in these innovative foundations.

© SIF

© EEW

Aktien-Gesellschaft der Dillinger Hüttenwerke, Werkstraße 1, 66763 Dillingen/Saar, Telefon: +49 6831 47 0, Telefax: +49 6831 47 2212, Sitz: Dillingen/Saar, Registergericht: Amtsgericht Saarbrücken HRB 23001, Vorsitzender des Aufsichtsrats: Reinhard Störmer, Vorstand: Stefan Rauber (Vors.), Joerg Disteldorf, Daniël Nicolaas van der Hout, Dr. Peter Maagh, Markus Lauer, Jonathan Weber

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.

Imprint

Privacy policy

Copyright © 2016 Dillinger. All rights reserved.