|

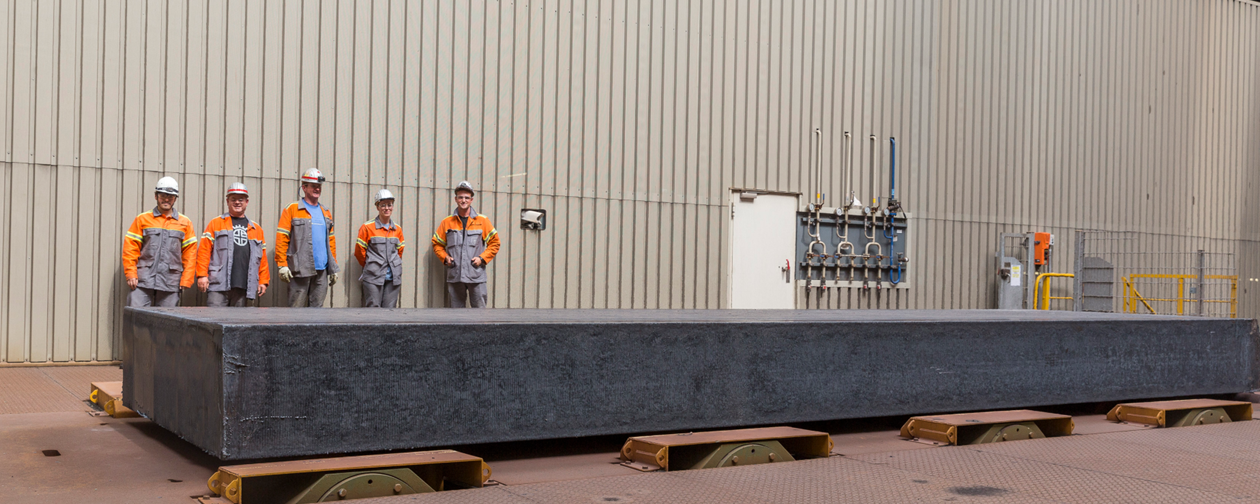

Slab thickness of 600 mm cast for the first time anywhere in the world on Dillinger's CC 6 continuous caster The record Once casting of 500 mm thick slabs had been achieved back in 2015, Dillinger's engineers soon set their sights on the next target: the aim was then to boost the productivity of this machine even further and to advance into new dimensions in terms of size and grades of steel. After several months of demanding development work and once all simulations had been successfully completed, the development and commissioning team raced ahead toward the goal of "going live". On 25 July 2017, everything was ready: and then the first strand was successfully cast in a world record slab format - with a cross-sectional area of up to 2,200 mm x 600 mm! Benefits for the customer The slabs cast on CC 6 permit production of heavy plates of extremely large dimensions and individual weights. "CC 6 enables us to produce greater quantities of thick plates in shorter times. The benefits for our customers, in the offshore wind-power industry, for example, and in the boiler and pressure-vessels sector, are thus found in the lower need for welding on large components, and thus in the time gains for completion of such projects. This new machine permits, not least of all, the further development of new steels with ultra-high surface specifications and out-of-the-ordinary dimensions", explains Dr. Bernd Münnich, Executive Officer, Technical Division, at Dillinger, examining the process advances now achieved.

Renowned Dillinger continuous-casting technology Dillinger's researchers and metallurgists have unceasingly pursued the development of the continuous-casting process. The company achieved pole position in this technology as long ago as 1961, with the commissioning of the world's first twin-strand caster for the continuous casting of heavy slabs. All Dillinger's continuous casters apply the vertical-casting method, which - like no other process - assures production of feed material of the very highest quality for the production of heavy plate. Continuous Caster 5, commissioned in 1998 and modernised in 2010, is also one of the most productive vertical casters and itself held the world record, for casting of a slab thickness of 450 mm, until 2015. CC 6 is, ultimately, the consistent and logical further development of Dillinger's vertical continuous-casting technology for achievement of even greater slab thicknesses, of 500 and 600 mm. These thicknesses are made possible by the fact that the strand is flame cut into smaller units while still in the vertical section of the machine. And the new "top scores" were achieved on this very CC 6 machine, at 500 mm thickness in the autumn of 2015, followed by 600 mm thickness in July 2017.

|